📊 Flowcharts

Launch the interactive flowchart builder in a new window so you can keep this guide open for reference.

What is a Flowchart?

A flowchart is a visual diagram that shows the steps in a program from start to finish. It helps you plan your robot's behavior before you write any code!

Why use flowcharts?

- Plan your program logic before coding

- See the flow of decisions and actions clearly

- Find problems in your logic early

- Communicate your ideas to teammates

- Debug programs more easily

Flowchart Shapes for VEX Programming

Square

Start/Stop Program

Rectangle

Action/Process

Up Triangle

Conditional (IF)

Down Triangle

End Conditional

Magenta Rectangle

Forever Loop

Green Rectangle

TRUE Path

Orange Rectangle

FALSE Path (ELSE)

Flowchart Examples

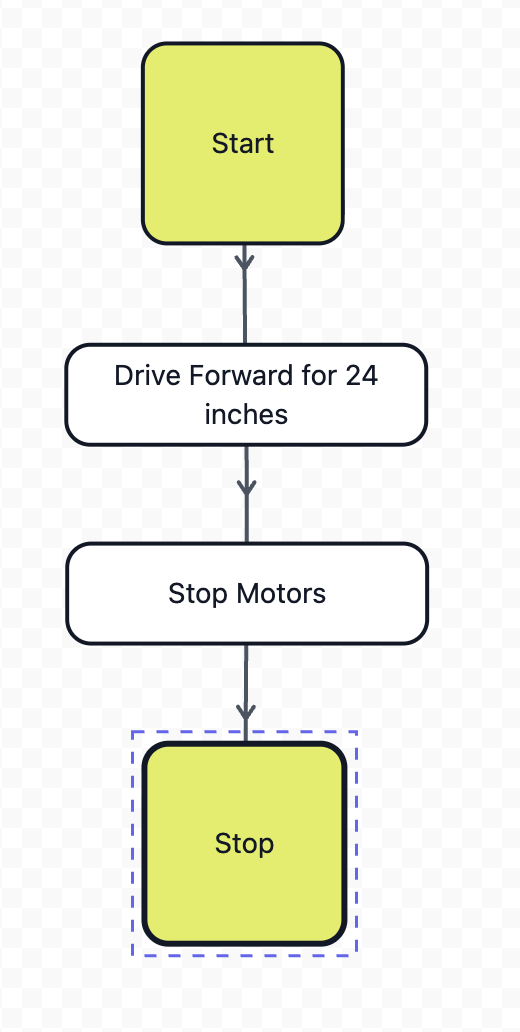

Example 1: Simple Forward Drive

Task: Robot drives forward for 3 rotations then stops.

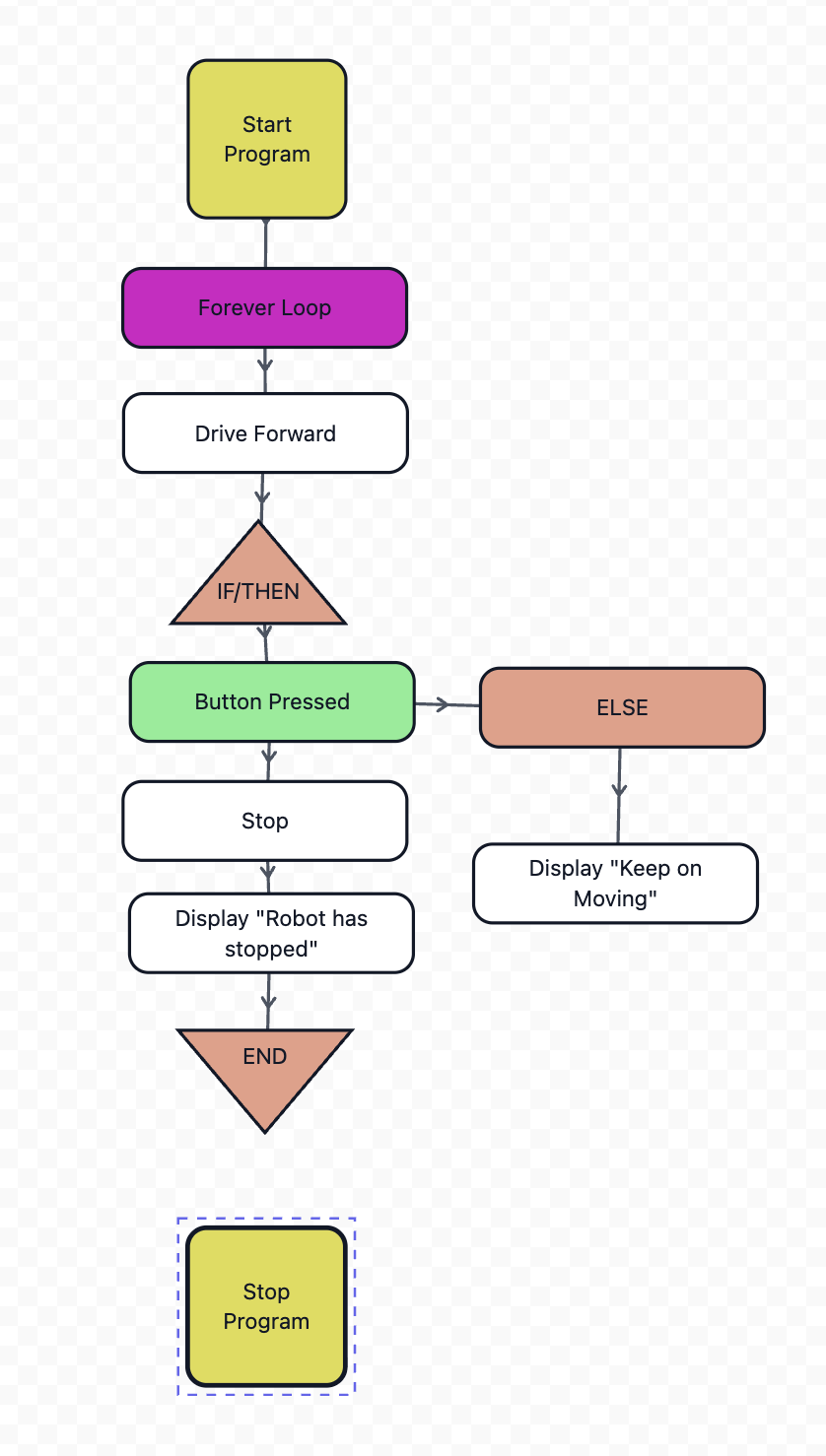

Example 2: Bumper Stop Program

Task: Drive forward until bumper is pressed, then stop.

Practice Exercise: Create Your Own Flowchart!

Challenge: Draw a flowchart for this program:

Shapes you'll need:

- 1 Green Square (START)

- 1 Blue Rectangle (Read Sensor)

- 2 Orange Up Triangles (IF conditions)

- 3 Blue Rectangles (Actions: Turn Left, Turn Right, Drive Forward)

- 1 Blue Rectangle (Stop Motors)

- 2 Purple Down Triangles (END IF)

- 1 Red Square (STOP)

Tip: Draw it on paper first! Remember to label YES/NO paths from conditionals.

- Always start with a START shape and end with a STOP shape

- Use arrows to show the direction of flow

- Label conditional branches clearly (YES/NO or TRUE/FALSE)

- Every UP triangle (IF) needs a matching DOWN triangle (END IF)

- Keep it neat and organized - easier to understand!

- Test your flowchart by following the arrows step-by-step

📊 Variables

What are Variables?

Variables are containers that store information in your program. Think of them like labeled boxes where you can keep numbers, text, or true/false values.

Types of Variables:

- Number: Stores numeric values (e.g., distance, speed, counter)

- Boolean: Stores true/false values (e.g., is robot moving?, is sensor triggered?)

- String: Stores text (e.g., "Forward", "Stopped")

Practice Example 1: Creating and Displaying a Variable

Challenge: Learn how to create a variable and display its value on the brain screen.

Step-by-step instructions:

- Open VEX V5 Code Visual Blocks

- Go to the Logic category (orange blocks)

- Click "Make a Variable" button

- Name your variable "score"

- Drag the "set [score] to [0]" block into your workspace

- Change the value from 0 to 10

- From the Events category, drag a "when started" block to the top

- From the Screen category, drag a "print [ ]" block below

- Return to the Logic category and drag the oval "score" variable block

- Place the "score" variable block into the empty slot of the "print [ ]" block

Goal: Display the value of "score" on the brain screen.

Practice Example 2: Changing Variable Values

Challenge: Create a program that changes the robot's speed by updating a variable.

Step-by-step instructions:

- Open VEX V5 Code Visual Blocks

- Go to the Logic category (orange blocks)

- Click "Make a Variable" button

- Name your variable "driveSpeed"

- From Events, drag "when started" block to workspace

- From Logic, drag "set [driveSpeed] to [0]" and change the value to 25

- From Drivetrain, drag "set drive velocity to [0] %" block

- From Logic, drag the oval "driveSpeed" variable block into the velocity slot

- From Screen, drag "print [ ]" block

- From Logic, drag the oval "driveSpeed" variable into the print block

- From Drivetrain, drag "drive [forward]" block

- From Control, drag "wait [1] seconds" and change to 3 seconds

- From Logic, drag another "set [driveSpeed] to [0]" and change value to 100

- From Drivetrain, drag another "set drive velocity to [0] %" block

- From Logic, drag the oval "driveSpeed" variable into the velocity slot

- From Screen, drag "print [ ]" block

- From Logic, drag the oval "driveSpeed" variable into the print block

Goal: The robot starts driving forward at 25% speed (showing "25" on the screen), then after 3 seconds accelerates to 100% speed (showing "100" on the screen) to demonstrate how changing a variable's value changes the robot's behavior!

🔀 Conditional Statements

What are Conditionals?

Conditional statements let your robot make decisions based on conditions. They follow the pattern: "IF this is true, THEN do this, ELSE do something else."

Block Types:

- IF-THEN: Execute code only if condition is true

- IF-THEN-ELSE: Execute one block if true, another if false

- IF-THEN-ELSE IF-THEN-ELSE: Check multiple conditions in order

- WAIT UNTIL: Pause program until a condition becomes true

- REPEAT UNTIL: Keep repeating actions until a condition becomes true

- REPEAT (x): Repeat actions a specific number of times

- FOREVER: Repeat actions continuously without stopping

- WHILE: Repeat actions as long as a condition remains true

Practice Example 1: Temperature Check

Challenge: Display different messages based on motor temperature.

Pseudocode:

Test it: Run motors for a while and see the message change.

Practice Example 2: Multi-Speed Selector

Challenge: Use IF-THEN-ELSE IF-THEN-ELSE to set different speeds based on button presses.

Logic:

Practice Example 3: Battery Level Warning

Challenge: Check battery percentage and respond appropriately.

Logic:

Practice Example 4: Count Down Timer

Challenge: Create a count down timer to lift off.

Logic:

🔗 Logic Operators

What are Logic Operators?

Logic operators combine multiple conditions to make complex decisions.

Operators:

- AND: Both conditions must be true

- OR: At least one condition must be true

- NOT: Inverts the condition (true becomes false)

Comparison Operators: = (equal), ≠ (not equal), > (greater), < (less), ≥ (greater or equal), ≤ (less or equal)

Practice Example 1: AND Operator - Safe to Move

Challenge: Robot should only move if BOTH battery is good AND temperature is OK.

Logic:

Practice Example 2: OR Operator - Emergency Stop

Challenge: Stop robot if ANY emergency condition is met.

Logic:

Practice Example 3: Complex Logic - Smart Navigation

Challenge: Combine multiple operators for intelligent behavior.

Logic:

What this does: If something is close AND you're not overriding, turn. If path is clear OR you force it, go fast. Otherwise, go slow.

Practice Example 4: Range Checker

Challenge: Check if a value is within a range.

Logic:

📏 Range Finder (Distance Sensor)

🔧 Hardware Setup

- Connect the VEX Distance Sensor to a 3-wire port (e.g., Port A, B, C, etc.)

- Ensure the sensor is firmly seated in the port

- Mount sensor facing forward on your robot

- Keep sensor lens clean for accurate readings

In VEXcode Blocks:

- Go to Devices menu

- Add device → Distance Sensor

- Name it (e.g., "FrontDistance")

- Select the 3-wire port you used

Sensor Range: Detects objects from ~20mm to 2000mm (2 meters)

How It Works

The Distance Sensor uses ultrasonic waves (sound waves) to measure how far away objects are. It sends out a sound pulse and measures how long it takes to bounce back.

Key Blocks:

Distance found by FrontDistance- Returns distance in mmIs object detected by FrontDistance- Returns true/false

Practice Example 1: Object Detection

Challenge: Stop the robot when it gets close to a wall.

Algorithm:

Skills practiced: Reading sensor values, conditionals, robot control

Practice Example 2: Variable Speed Based on Distance

Challenge: Robot slows down as it gets closer to objects.

Algorithm:

Practice Example 3: Parking Challenge

Challenge: Drive forward and stop exactly 200mm from a wall.

Algorithm:

Make it harder: Add points based on accuracy!

👁️ Vision Sensor

🔧 Hardware Setup

- Connect Vision Sensor to a Smart Port (1-21) on the V5 Brain

- Smart ports have a different connector than 3-wire ports

- Mount sensor with clear field of view

- Ensure good lighting in your environment

In VEXcode Blocks:

- Go to Devices menu

- Add device → Vision Sensor

- Name it (e.g., "Vision")

- Select the Smart Port you used

- Configure Color Signatures: Use VEX Vision Utility to teach the sensor colors

Setting Up Color Signatures

Before using the Vision Sensor, you need to "teach" it what colors to look for:

- Connect brain to computer

- Open VEX Vision Utility (in VEXcode)

- Point sensor at colored object you want to detect

- Click "Capture" to save that color as a signature (SIG_1, SIG_2, etc.)

- Give it a name like "RED_CUBE" or "GREEN_BALL"

- Download signatures to the sensor

Key Blocks:

Take snapshot with Vision.SIG_1- Look for a specific colorIs Vision detecting signature SIG_1- Returns true/falseVision largest object centerX- X position of detected objectVision largest object width- How wide the object appears

Practice Example 1: Color Detection

Setup: Configure SIG_1 for red objects

Challenge: Robot says "Found it!" when it sees a red object.

Algorithm:

Practice Example 2: Object Tracking

Setup: Configure SIG_1 for a colored object

Challenge: Robot turns to keep the object centered in view.

Algorithm:

Explanation: Vision sensor has ~316 pixels width. Center is around 158. We use 120-200 as "close enough" to center.

Practice Example 3: Multi-Color Sorting

Setup: Configure SIG_1 = RED, SIG_2 = BLUE, SIG_3 = GREEN

Challenge: Robot responds differently to each color.

Algorithm:

Practice Example 4: Object Size Detection

Challenge: Determine if object is close or far based on its size.

Algorithm:

Concept: Objects appear larger when closer to camera!

🔘 Bumper Switch

🔧 Hardware Setup

- Connect Bumper Switch to a 3-wire port (e.g., Port A, B, C, etc.)

- The switch has three wires - ensure proper orientation

- Mount on robot where it will hit obstacles first (front bumper)

- Test by pressing it manually - you should feel a click

In VEXcode Blocks:

- Go to Devices menu

- Add device → Bumper Switch

- Name it (e.g., "FrontBumper", "RearBumper")

- Select the 3-wire port you used

How It Works

A bumper switch is a simple digital sensor that's either pressed or not pressed. It's perfect for collision detection!

Key Blocks:

FrontBumper pressed- Returns true when switch is pressedFrontBumper released- Returns true when switch is not pressedWhen FrontBumper pressed- Event-based programming (advanced)

States:

- Pressed (true): Switch is pushed in

- Released (false): Switch is not pushed

Practice Example 1: Basic Collision Detection

Challenge: Stop robot when bumper hits something.

Algorithm:

Skills practiced: Reading digital sensor, wait until command

Practice Example 2: Reverse and Continue

Challenge: When robot hits wall, back up and continue.

Algorithm:

Practice Example 3: Collision Counter

Challenge: Count how many times the robot hits obstacles.

Algorithm:

Explanation: The "wasPressed" variable prevents counting the same collision multiple times.

Practice Example 4: Dual Bumper Navigation

Setup: Add FrontBumper and RearBumper to your robot

Challenge: Robot responds differently based on which bumper is hit.

Algorithm:

Practice Example 5: Bumper + Logic Operators

Challenge: Complex behavior using bumper with other conditions.

Algorithm:

Concept: After 5 collisions, robot switches to manual mode for safety!

Practice Example 6: Touch-to-Start

Challenge: Use bumper as a start button.

Algorithm: