Lesson 1.2 – Worm and Bevel Gears

Discover how worm gears create extreme reduction ratios and self-locking mechanisms. Learn how bevel gears change rotation direction by 90 degrees. Build a precision turntable combining both gear types with compound stages.

← Back to Robotics Home ← Back to Lesson 1.1 – Spur GearsLesson Overview

What makes worm and bevel gears special in robotics.

In this lesson you will explore two specialized gear types that change the direction of rotation. Worm gears create massive reduction ratios (up to 84:1 in VEX) and can self-lock to prevent back-driving. Bevel gears transmit power at 90-degree angles, perfect for changing rotation planes. You will build three mechanisms: (1) a worm gear reducer that demonstrates self-locking, (2) a bevel gear direction changer, and (3) a precision turntable combining compound spur gears, worm gear, and bevel gears for extreme torque and control.

- Explain how a worm gear works and calculate its ratio

- Describe self-locking and when it's useful

- Show how bevel gears change rotation direction

- Identify perpendicular shafts vs parallel shafts

- Build mechanisms that change rotation planes

- Combine multiple gear types in one system

- Calculate total ratios through mixed gear trains

- Part A: Worm gear concepts and math

- Part B: Bevel gear principles and applications

- Part C: Three build activities:

- Activity 1: Worm Gear Reducer (self-locking test)

- Activity 2: Bevel Gear Corner Drive

- Activity 3: Precision Turntable (combined system)

- Part D: Check Your Understanding questions

Concepts & Vocabulary

Understanding worm and bevel gear mechanics.

1. Worm Gears – The Power of the Spiral

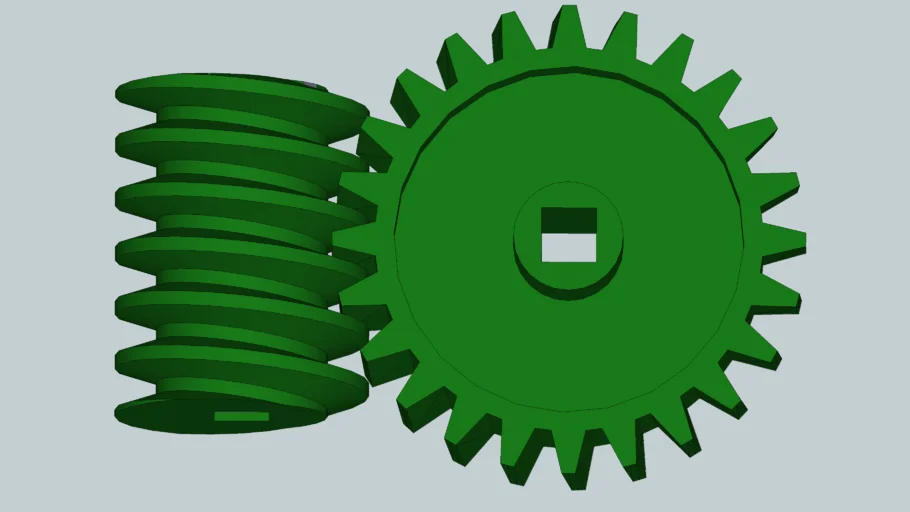

A worm gear consists of a spiral thread (the worm) that meshes with a spur gear (the worm wheel). The worm looks like a screw, and each complete turn advances the worm wheel by one tooth. This creates extreme reduction ratios in a single stage.

- Worm: The screw-like driver gear

- Worm Wheel: The spur gear driven by the worm

- Lead: How far the worm advances per revolution

- Helix Angle: The angle of the spiral thread

- Self-Locking: When the gear can't be back-driven

- Single-Start: Worm with one spiral thread (VEX standard)

- Perpendicular Shafts: Input and output at 90°

Formula (single-start worm):

Ratio = Number of Teeth on Worm Wheel ÷ 1

VEX Examples:

- Worm → 12T wheel = 12:1

- Worm → 36T wheel = 36:1

- Worm → 60T wheel = 60:1

- Worm → 84T wheel = 84:1

Note: Always massive reduction, never used for speed increase.

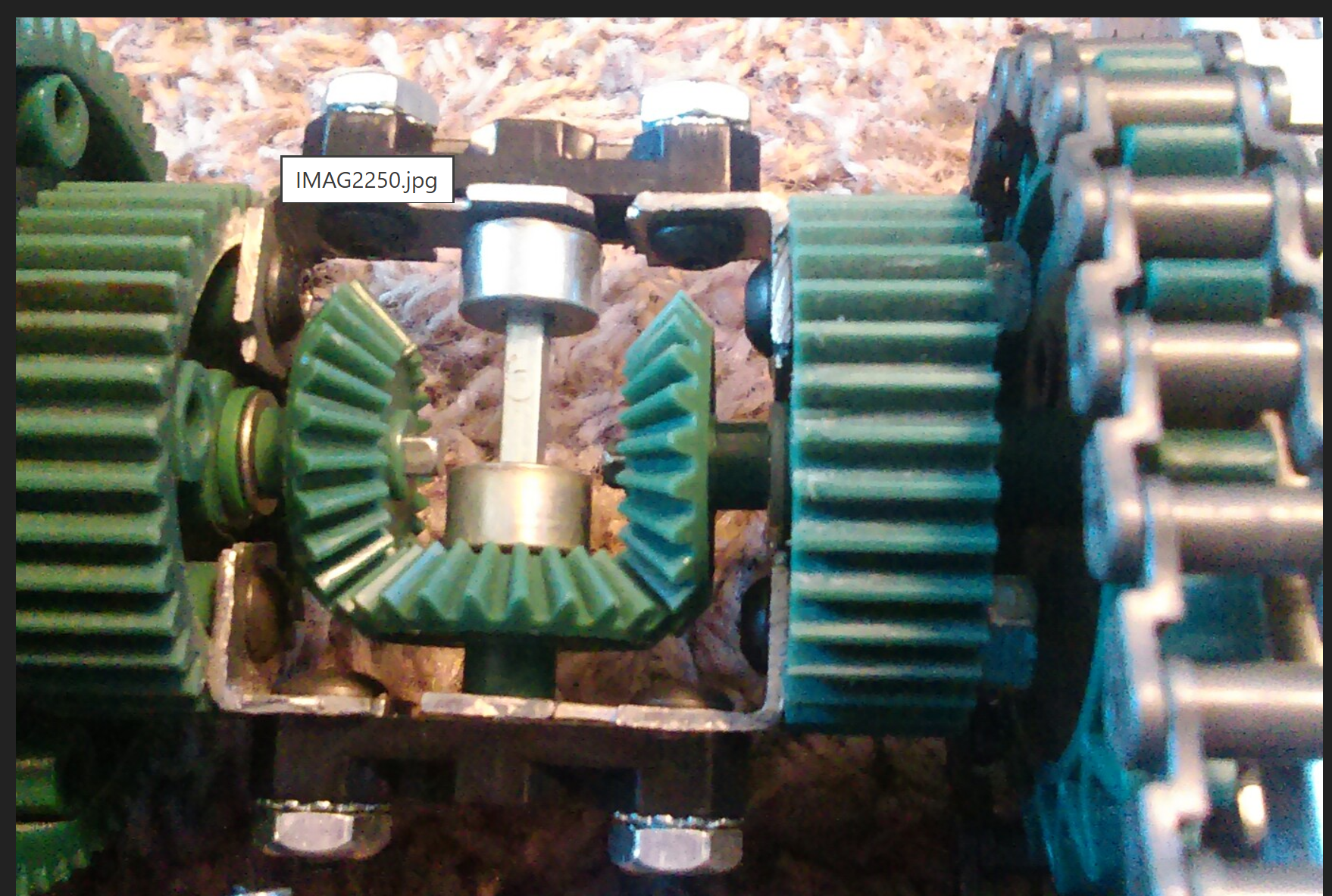

2. Bevel Gears – Turning Corners

Bevel gears have teeth cut at an angle, forming a cone shape. When two bevel gears mesh, they transmit rotation between perpendicular shafts. Think of them as the corner pieces in your gear train.

- Bevel Gear: Cone-shaped gear for 90° drives

- Pitch Cone: The imaginary cone of the gear

- Miter Gears: Two equal bevel gears (1:1 ratio)

- Crown Gear: Bevel gear with 90° teeth (flat face)

- Perpendicular Axes: Shafts meet at 90°

- Apex: Point where cone axes intersect

Same formula as spur gears:

Ratio = Driven Teeth ÷ Driver Teeth

VEX Bevel Options:

- 12T → 12T = 1:1 (miter pair)

- 12T → 36T = 3:1 (reduction)

- 36T → 12T = 1:3 (speed up)

- 24T → 24T = 1:1 (common size)

Key: Changes direction AND can change ratio.

3. Comparison Table

| Feature | Spur Gears | Worm Gears | Bevel Gears |

|---|---|---|---|

| Shaft Orientation | Parallel | Perpendicular (90°) | Perpendicular (90°) |

| Typical Ratio Range | 1:5 to 5:1 | 12:1 to 84:1 | 1:3 to 3:1 |

| Self-Locking | No | Yes (usually) | No |

| Efficiency | 95-98% | 40-85% | 90-95% |

| Back-Driving | Easy | Difficult/Impossible | Easy |

| Common Use | Speed/torque trade | High reduction, holding | Direction change |

Math Check: Spur ratio = 5 × (60 ÷ 36) = 25/3 ≈ 8.333.

Multiply by the worm (× 24) and bevel (× 1) to get

200:1 total. With a 200 RPM motor cartridge you get

200 ÷ 200 = 1 RPM at the turntable—exactly one revolution per minute.

Visual Models

Real-world examples and analogies.

A guitar tuning peg uses a worm gear. You turn the peg many times (the worm) to slowly tighten the string (the wheel). It's self-locking so string tension can't unwind the peg. This is exactly how your robot's worm gear works – many input turns for precise output control.

In a car, the engine rotates the driveshaft front-to-back. Bevel gears in the differential turn this rotation 90° to spin the wheels side-to-side. Your robot uses the same principle to change rotation direction around corners.

Build & Code Activities

Three hands-on builds to master these gear types.

Shared Coding Setup

Use the same test program for all builds to compare fairly:

- Open VEXcode V5 and create a new Blocks project

- Add your Smart Motor device (name it

TestMotor) - Create this standard program:

- When started → Set motor velocity to 25%

- Spin motor forward for 10 seconds

- Stop motor

Activity 1: Worm Gear Reducer (Self-Locking Test)

Build a worm gear reducer and test its self-locking property. See how it holds position without power.

What You Need

- VEX V5 Brain, Smart Motor, battery, cables

- VEX worm gear (single-start)

- 36T and 60T spur gears to test as worm wheels

- Two perpendicular shafts, bearings, collars

- Structural pieces to mount at 90°

- Small weight or load to test holding

Build Steps

- Mount the motor horizontally with the worm gear on its shaft

- Mount a vertical shaft perpendicular to the worm, with a 36T gear meshing with the worm

- Ensure the gears mesh smoothly – worm gears need precise spacing

- Add a wheel or arm to the output shaft as a position indicator

- Run your test program and observe:

- Count output rotations vs motor rotations

- Note the slow, precise movement

- After the program stops, try to turn the output by hand – it should resist (self-locking)

- Replace the 36T with a 60T gear and repeat the test

- Theoretical ratio (teeth on wheel ÷ 1)

- Observed output speed (very slow!)

- Can you back-drive it? (turn output by hand)

- How much weight can it hold without slipping?

Activity 2: Bevel Gear Corner Drive

Build a 90-degree corner drive using bevel gears. Compare different ratio combinations.

What You Need

- Same electronics as Activity 1

- VEX bevel gears (12T and 36T, or 24T pairs)

- Two perpendicular shafts

- Corner mounting structure

- Output wheel or flag

Build Steps

- Mount the motor horizontally with a 12T bevel gear

- Mount a vertical shaft with a 12T bevel gear meshing at 90°

- Bevel gears must mesh at their pitch cones – adjust carefully!

- Run the test program and observe:

- 1:1 ratio means same speed in and out

- Power turns the corner smoothly

- Try back-driving – unlike worm gears, it should turn freely

- Replace with 12T driver and 36T driven for 3:1 reduction

- Note the speed decrease and torque increase

Activity 3: Precision Turntable (Combined System)

Build a precision turntable that hits exactly 200:1 overall reduction. The new configuration keeps the worm + bevel finish but streamlines the spur stages so a 200 RPM motor outputs a clean 1 RPM at the turntable.

🎯 Turntable Gear Train Design

What You Need

- VEX V5 Brain, Smart Motor (18:1 cartridge recommended)

- Multiple shafts (at least 5), bearings, collars, spacers

- Gears: Multiple 12T, two 60T, one 36T spur gears

- One worm gear

- 24T spur gear (for worm wheel)

- Two 24T bevel gears

- Large wheel or disk for turntable top

- Extensive structural pieces for multi-stage mounting

Build Steps

- Stage 1 – 12T to 60T (5:1):

- Motor shaft: 12T driver gear

- Shaft A: 60T driven gear

- Add a 36T driver gear on Shaft A (same shaft as the 60T)

- Stage 2 – 36T to 60T (5/3 ≈ 1.667:1):

- Shaft A's 36T drives a 60T gear on Shaft B

- Mount the worm gear on Shaft B alongside the 60T

- Stage 3 – Worm Reduction (24:1):

- Mount perpendicular shaft with 24T spur as worm wheel

- This shaft should be vertical if worm is horizontal

- Stage 4 – Bevel Corner (1:1):

- Add 24T bevel to the worm wheel shaft

- Mount final horizontal shaft with matching 24T bevel

- Attach turntable wheel to this final shaft

- Testing:

- Run the motor at 200 RPM (e.g., 100% on an 18:1 cartridge)

- Mark the starting position on the turntable rim

- It should complete one full revolution in one minute—adjust friction until it does

Calculate Total Ratio

| Stage | Calculation | Stage Ratio | Running Total |

|---|---|---|---|

| Stage 1 (Motor → Shaft A) | 60 ÷ 12 | 5:1 | 5:1 |

| Stage 2 (Shaft A → Shaft B) | 60 ÷ 36 | 5/3 ≈ 1.667:1 | 25/3 ≈ 8.33:1 |

| Stage 3 (Worm Gear) | 24 ÷ 1 | 24:1 | 200:1 |

| Stage 4 (Bevel Corner) | 24 ÷ 24 | 1:1 | 200:1 total |

- Draw the complete gear train with all tooth counts labeled

- Show the calculation for each stage and total ratio

- Measure actual turntable rotation after 10 seconds

- Calculate theoretical vs actual RPM

- Explain advantages of combining gear types

- List three real-world applications for this mechanism

Check Your Understanding

Complete these questions and add to your engineering notebook.